Today is Tesla’s first annual Battery Day. It’s a day to focus on EV technology and what’s next in advancing it towards widespread consumer adoption. We’ve been focusing on how to maximize today’s EV batteries to make them high density, quick charge, affordable and safe for years. At Global Graphene Group, we know that EVs are the future, and our drop-in graphene-enhanced solutions can help EV manufacturers improve their battery function, today.

Elon Musk, Tesla’s CEO, tweeted yesterday that today’s Battery Day announcements will include news on long-term manufacturing of EV’s, including semis, cybertrucks and a roadster.

A leak surfaced recently that a larger cell will be announced during today’s Battery Day. The rumored 4070 cell would be used in batteries for electric semi and cybertrucks. No matter which size the battery cell will be, the heat dissipation will be a more serious problem than the current 2170 cell because heat will need to travel at least twice the distance from the core of the cell.

Heat can be a big spoiler for the EV batteries companies like Tesla are banking on. Heat builds up when batteries are super charged and under continuous driving conditions. That’s exactly what online leaks suggest Tesla has planned with batteries for semi and cybertrucks. While it makes sense to prioritize these types of vehicles in terms of their environmental impact, having delivery trucks and freight carriers with massive batteries driving continuously add up to a potential power disaster.

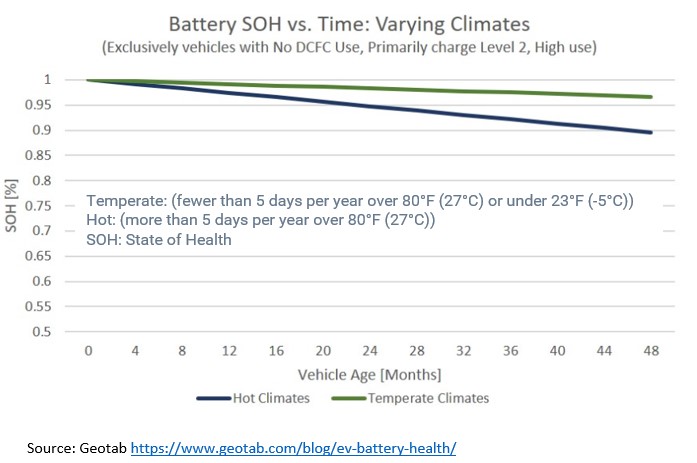

There’s already evidence of EV batteries losing their power density and becoming unsafe in high heat areas – think Arizona, Texas, Nevada and other areas of the country that tend to heat up. In some of these areas, they experience more than five days per year with temperatures climbing over 100°F. Much of the country experiences temperatures above 80°F throughout the summer months. Those high temps can decrease the battery life dramatically. Lithium-ion batteries have a decreased lifespan under high and continuous heat situations. Vehicles that are heavily used throughout the day with little break and ones driving in tropical weather areas are affected.

Specifically, the corrosion reactions between the battery’s electrolyte and the current collector can be very serious above 113°F. And that is why many EV owners observed reduced charging current when their battery pack reached 113°F during fast-charging in order to prevent the damage. Research shows even just parking outside when the ambient temperature is above 90°F can permanently damage the EV battery. E-trucks are supposed to run for hours continuously every day which will damage the battery pack from heat more than passenger EVs.

So how to EV manufacturers mitigate the high heat issues for their batteries? Of course, a nice cooling system can solve this problem, but it also consumes the energy from the battery and thus shortens the mileage per charge. They could adjust the battery’s power during fast charging when the battery temperature hits the upper temperature limit. But some real data showed up to 50% more time will be needed for fast charging in hot climates, which is a negative for consumers. EV owners could park in the shade or avoid driving during hot days, but that’s not always possible.

While many consider solid-state batteries to be the “holy grail” of EV batteries, but they’re still years away from commercialization. At G3, we have developed a portfolio of graphene-enhanced battery solutions that bridge the gap between today’s lithium-ion batteries and tomorrow’s solid-state.

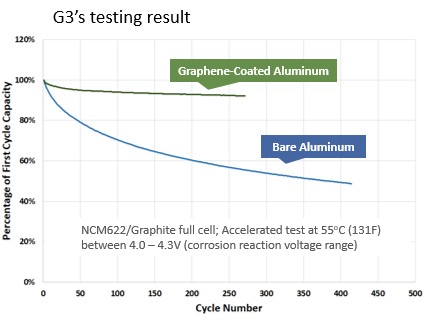

Our graphene-coated current collector performs much better than bare aluminum current collector, even at temperatures above 131° making it a good fit for military applications under extreme conditions. It would also benefit E-trucks and every EV that needs higher power and real fast-charging. The theory behind this is that HF generated from a chain reaction in electrolyte can damage the surface of the current collector in a Li-ion battery. The corrosion reaction will become more serious when temperatures or voltage are high.

G3‘s graphene-coated Al current collector solves this problem. We did an accelerated cycling test at 55°C between 4.0 and 4.3V, the voltage range the corrosion is serious. You can see that when commercial bare Al was used, the capacity dropped rapidly to <80% capacity retention within 50 cycles.

Our graphene-coated Al current collector can last over hundreds of cycles. 55°C might be considered as an extreme condition but actually the battery can reach this temperature fairly easily. Super-charging, parking under direct sunlight in summer or tropical areas, or continuously driving for hours will let the battery heat to over this temperature and damage the battery permanently. In the future, we will use this product in our cells to improve the cycle life, making it capable of high-power charge/discharge, and giving consumers worry-free parking for days of hot weather. Tesla and other EV OEMs can surely benefit from our graphene-coated current collector.

We’re ready to talk about our EV battery technology. Give us a call at 937-331-9884 or email [email protected] to schedule a time. Our drop-in solutions are ready now and will lower EV battery costs, increase their range and provide a safer battery. Widespread EV adoption is around the corner, and G3 is prepared to be part of the EV revolution.