Today, mobile devices play an integral part in people’s lives. Almost everyone has at least one smartphone, tablet or wearable device, and many have more. As demands for higher processing speeds and multi-functionality arise, these devices are required to perform efficiently at high rates of power consumption. This demand is further complicated as microprocessor speeds increase but device size remains as compact as ever.

Why Does Thermal Management Matter?

Let’s take a phone for example. When heat is not properly dissipated, thermal stresses build up inside which eventually lead to deteriorated performance before the device ultimately fails. The deteriorated performance results from a significant increase in device temperature known as overheating. Signs of overheating are seen by abrupt, unexpected app shutdowns, frozen screens, or a complete device shutdown. The overheating process consumes battery capacity at a significantly higher rate than normal, and results in having to recharge your battery much sooner than anticipated.

Market Opportunities for Thermal Management Components in Smartphones, Yole Development, November 2017

On top of that, the batteries in most cell phones are lithium-ion batteries and they are extremely sensitive to heat. Exposure to elevated temperatures speeds up their aging process and, in turn, cuts the battery life short.

How Do We Combat Overheating?

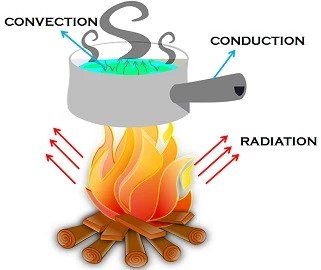

With the help of thermal management technology, there are ways to handle this thermal dilemma. Recall that heat transfer may occur from one place to another via conduction, convection, or radiation. Conduction is the transfer of heat energy by direct contact, convection is the movement of heat by actual motion of matter, and radiation is the transfer of energy with the help of electromagnetic waves. Both convection and radiation have been shown to have minimal effect on cooling in mobile devices, [1] therefore conduction is the best solution.

Difference between convection, conduction, radiation

How Can We Conduct Heat Away from the Source Efficiently?

Heat spreaders, by introducing a solid conduction path between the components and the case, effectively minimize the temperature of hot spots and evenly distribute localized heat flux over a large area, which helps dissipate heat more efficiently. Due to their low profile and conformability, heat spreaders can be placed in close proximity to the microprocessor (i.e., heat source) and minimize the thermal resistance effects that would otherwise result from air gaps. While heat pipes and thermal interface materials have also been explored as options for thermal management, heat spreaders have proven to be the ideal choice.

What Is In A Heat Spreader?

Materials that have been used in heat spreaders include metals, composites, and graphite. Metals such as aluminum and copper have stood out as the best options owing to their relatively high thermal conductivity (237 and 401 W/m-K respectively) and relatively low costs. Copper’s more isothermal base has led to its use over aluminum as it reduces spreading resistance [2].

Composites of steel sandwiched with aluminum, copper, or graphite have also been explored to impart bending resistance and thermal conductivity in the device, but still present a weight:volume ratio challenge. The need to balance thermal management performance with overall device weight has resulted in concerns about the use of metals.

Graphite has recently become a more desirable material for thermal management in mobile devices due to its thermal conductivity (500 W/m-k) and low density, which is 4 times less than copper. It is conformable and has the ability to minimize contact resistance; however, the brittle nature of graphite presents limitations to the manufacturing process.

So What Is The Answer?

The next generation of thermal management is expected to fall on the shoulders of graphene. Graphene’s excellent thermal conductivity (up to 5,300 W/m-K) allows it to be leveraged in anything ranging from phones to drones in the form of thermal foils and thermal pastes. Not only does graphene offer exceptional thermal conductivity, but it also acts as an electromagnetic shield (EMI) and is very lightweight so it won’t add significantly to the weight of the device.

Summary:

· As more power is required for devices, more efficient methods of cooling are needed to prevent overheating.

· Overheating due to poor thermal management can cause app failures, frozen screens and even compete device shutdown.

· Thermal management via conduction is the best route to efficiently cool electronic devices.

· Heat spreaders can be made from metals such as aluminum and copper, composites of steel, and graphite, but each pose their own set of challenges.

· Graphene, the next generation of thermal management materials, offers exceptional thermal conductivity while also being lightweight.

Sources:

[1] T. T. Lee, “Thermal management of handheld telecommunication products « electronics cooling magazine –focused on thermal management, TIMs, fans, heat sinks, CFD software, LEDs/lighting,” in Electronics

Cooling, 2016. [Online]. Available: http://www.electronics-cooling.com/1998/05/thermal-management-ofhandheld-telecommunication-products/. Accessed: Jun. 28, 2016.

[2] A. McWilliams, “The market for thermal management technologies – SMC024K,” in BCC Research, 2016. [Online]. Available: http://www.bccresearch.com/market-research/semiconductor-manufacturing/the-marketfor- thermal-management-technologies-report-smc024k.html. Accessed: Jun. 28, 2016.