The Problem

Lithium-ion Battery Industry

Cost

Battery Life

Battery Size

Safety

Storage Capacity

The Solution

Why G3 High Energy Sulfur / Graphene Cathode?

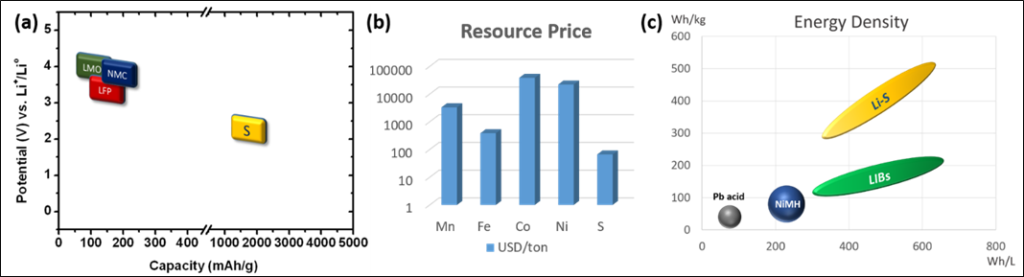

High Storage Capacity

High storage capacity increases hours per charge giving more time in between charges

Weight Reduction

Higher capacity results in higher energy density and thus smaller battery form factors

Increased Battery Life

Even with high capacity, battery life is not sacrificed

Why G3 High Energy Sulfur / Graphene Cathode?

Cost

The cost of G3 S/graphene composite will be driven down to <$10/kg

High Storage Capacity

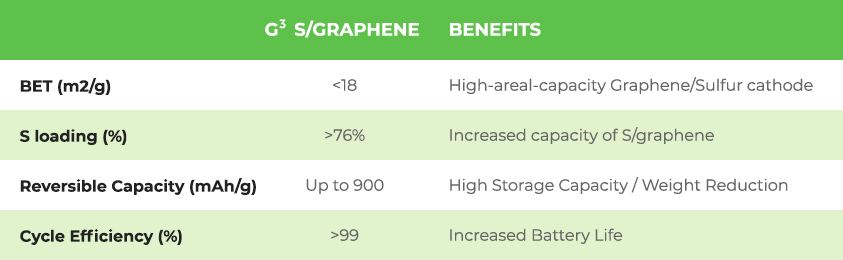

The high storage capacity of G3 S/graphene composite (up to 900 mAh/g) allows the battery to hold more charge and last longer between charging

Economy of Scale

The cost of G3 S/graphene composite can be driven down as the production capacity increases. The process for manufacturing is also scalable

Weight Reduction

Higher capacity results in higher energy density (>400 Wh/kg) and thus smaller battery form factors

High Cycle Efficiency

G3 S/graphene composite has an exceptional Cycle Efficiency even with its high capacity, which mean battery lifetime is not sacrificed

Operability

G3 S/graphene composite has very low BET and is a drop-in solution for cell manufacturers, requiring no additional processing

Benefits

What are the benefits or applications?

Capacity

Conventional cathodes (NCM, LFP, NCA):<250mAh/g

G3 S/graphene composite: >900 mAh /g

Cost

Conventional cathodes (NCM, LFP, NCA):

$20/kg - $60/kg

G3 S/graphene composite: < $10/kg

Energy Density

Conventional Li-ion batteries: < 300Wh /kg

G3 Li - S batteries: >400Wh/kg

Overview

Graphene-Sulfur

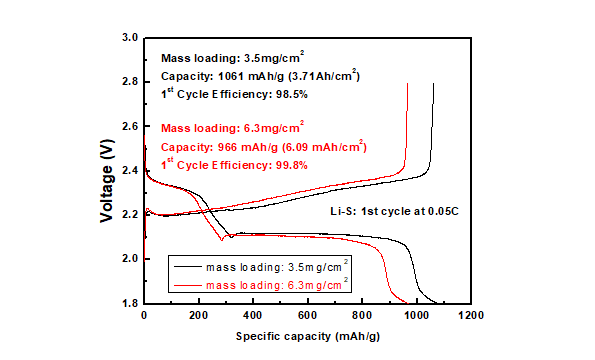

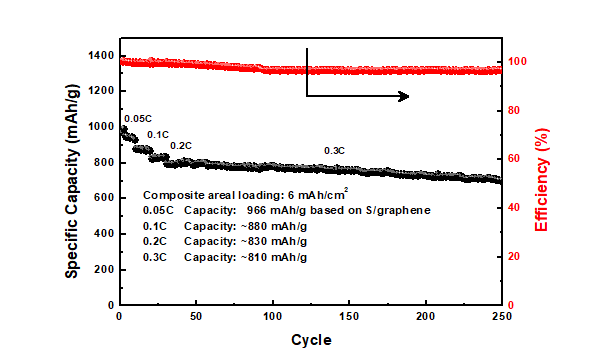

The Graphene-Sulfur electrode with a high sulfur composite areal loading (6 mAh/cm2) showed excellent cycle life, delivering a stable ~800 mAh/g capacity at 0.3C

At 0.3C, the data showed ~88% capacity retention for 250+ cycles, and the degradation rate (at 0.3C) is only 0.055%/cycle, suggesting excellent cycle retention for our Graphene-Sulfur cathode.